Modern control solution for aging Hot Wire Cutter.

A Hot Wire Cutter running on obsolete control equipment that was proving costly to both maintain and troubleshoot.

The Cutter was no longer capable of operating in variable temperature control, and a number of other features were either not working or required modification.

Due to the age of the machine and incomplete or missing documentation the customers own engineers were unable to make these changes, and DnA were asked to plan and carry out the upgrade.

Download this case study..

DnA Case Study - obsolete control system replaced on Hot Wire Cutter

Cone pulley and belt drive system replaced with a modern ABB drive solution

A Variable Speed Drive project replaces an existing troublesome cone pulley and belt mechanically based speed control system, utilising ABB ACSM1 drives and Siemens Flender gearboxes.

Drives and Automation Ltd were awarded the contract to upgrade the existing 24 axis paper machine drive system, which was based on a line shaft with cone pulleys and belts. The proposal was to convert the existing drive spindles into independent drives utilising AC geared motors and inverter control.

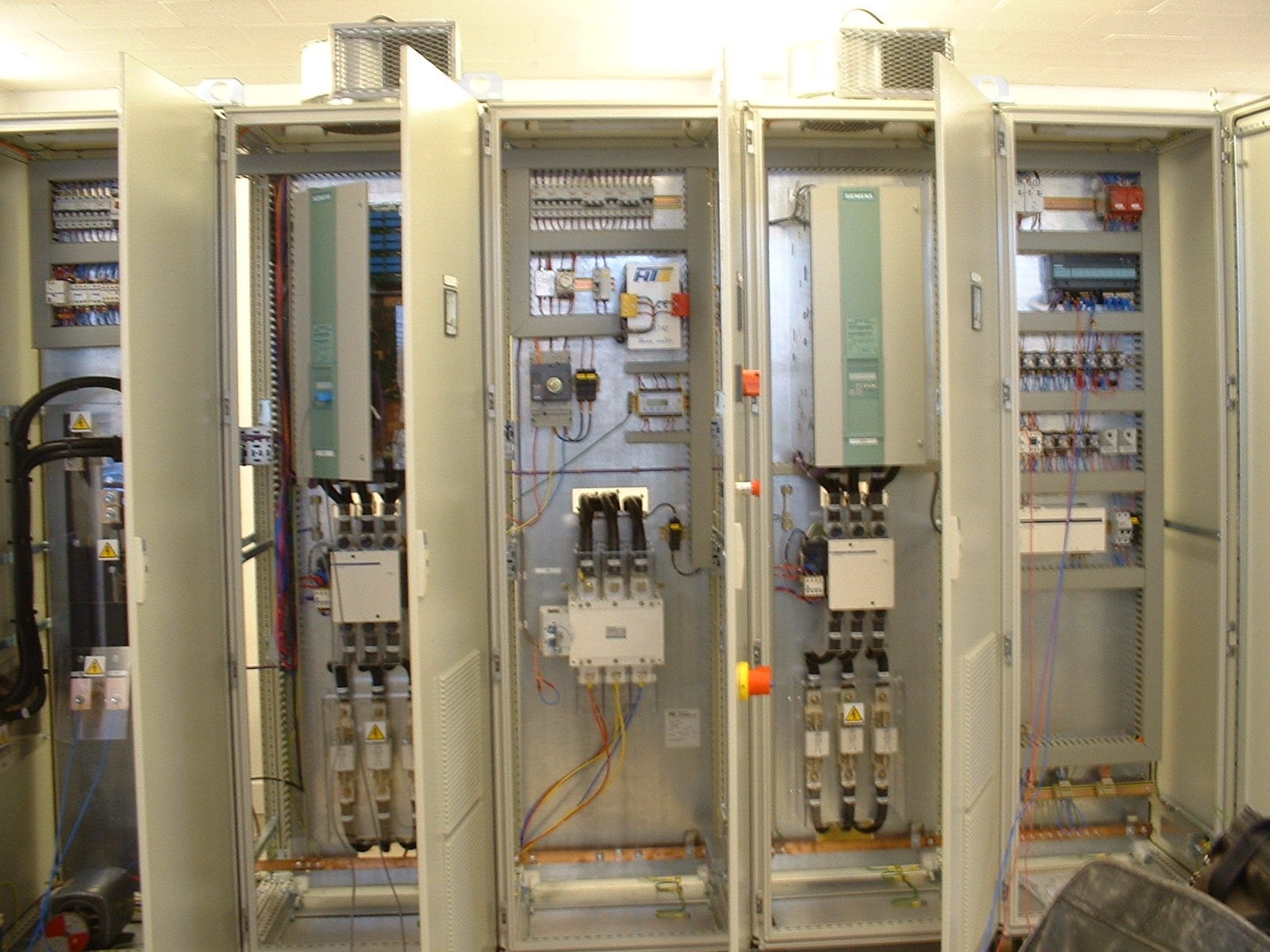

DC Drive upgrade, Laura Ashley Gravure wallpaper line

A Variable Speed DC Drive upgrade project replaced an existing troublesome DC control system, resulting in increased production and reduced downtime on the Texplan / Laura Ashley Gravure wallpaper line in Newtown, Powys.

Drives and Automation Ltd provided a complete drive control solution including the drive and PLC control panel suite.

Tubular Strander - DC to AC Conversion

A Variable Speed Drive AC conversion project replaces an existing troublesome DC control system and both reduces machine downtime and increases production on a Tubular strander.

Drives and Automation were asked to look at replacing the existing obsolete DC drive system with a full AC conversion, as reliability was becoming an issue.

250T Ladle Bay Crane Drives at Outokumpu

Drives and Automation carried out a £2.25M upgrade to three 250t cranes in Outokumpu's Sheffield based stainless works.

Using Allen Bradley and Pilz PLC systems and Control Techniques inverter drives, we replaced the existing slipring control system but retained the existing slipring motors to provide smooth, variable speed control over all crane axes.

DC Arc Fan Drive at Outokumpu, Sheffield

A new fan and inverter drive system improves control and maximises energy savings on the DC ARC fume extraction system at Outokumpu in Sheffield.

Drives and Automation replaced the existing fan at the same time as replacing the control system. The control system was replaced with an Allen Bradley PLC, inverter and overloads and an Intouch SCADA package to handle diagnostics.

800kW A.C Winch Drive System Installation at a Cheshire Salt Mine

A 3.3kV to 690V LV drive conversion replaces an obsolete slip ring motor control system with a modern ABB ACS800 regenerative inverter, supply transformer and motor.

The work carried improved both production and reliability at one of the UK’s largest salt mines

Scale Lane Footbridge in Hull

This innovative swing bridge over the River Hull is believed to be the first bridge in the world that allows pedestrians the unique experience of riding it while in motion.

Steel Vessel Tilt Drives at Tata Steel

Engineers from the BOS plant at Tata Steel in Scunthorpe approached Drives and Automation to investigate a longstanding reliability problem on the DC drive control system for the steel vessel.

We replaced the existing power stacks with Control Techniques Mentor II DC drives and FXM5 field controllers rated to cover the peak overload requirement of 2100A.

Slab Grinder Drives at Outokumpu, Sheffield

Replacing the existing hydraulic system with electrical drives and a servo positioning system has boosted the performance of the of the stainless steel slab grinder as well as reducing downtime.

DnA used Control Techniques Unidrive SP drives with an Allen Bradley PLC system and Intouch SCADA package to provide overall control of a system capable of grinding stainless steel slabs up to 15m long weighing 35 tonnes.

Electric Arc Furnace Control

The control system managing Outokumpu’s 90MVA Electric Arc Furnace had grown over the years to incorporate several different PLC’s of different manufacture, most being obsolete; fault finding had become very time consuming.

When Outokumpu's plant engineers took the decision to replace the complete control system Drives and Automation were awarded the £1.3M project to design, supply and commission the new system - which had to be completed and ready for production within the planned two week summer shutdown of 2012.

Lead Plant Fume Extraction

The original installation consisted of four 3.3kV motors two of 650kW and two of 410kW which were limited to no more than 4 starts per hour without risking damage to the windings. This meant the fume extraction fans running on for an additional 15 minutes even though demand had dropped just in case they were needed again due to the limitations on starting.

DnA won the £650k contract to replace the motors and control system with the primary objectives of saving energy, improving plant efficiency and reducing downtime. The replacement system consisted of 4 low voltage motors and installing low harmonic variable speed drives and saved over £200k in energy costs in its first year of operation.

Freightliner has reduced downtime on its second Arrol container crane by replacing the old drives with a new system provided by Drives and Automation Ltd.

With loads of up to 32 tonnes, safety was a major factor in the upgrade so DnA proposed a Pilz Multi PLC system controlling ABB DCS800 DC drives and the system was built into an existing control room on top of the crane.

Arrol Crane Drives at Freightliner, Garstang

Grab Crane Drives at Tata Steel, Scunthorpe

DnA replaced an outdated slipring motor control system with variable speed control to reduce downtime and maintenance headaches.

The new control system housed Control Techniques Unidrive inverters, an Allen Bradley Micrologix PLC along with a safety relay and Cresall dynamic braking resistors, all housed in a Rittal stainless steel cabinet mounted next to the control pulpit.

Static Cut Off Drives, Tata Tubes

Drives and Automation replaced an existing Mannesman system that had reached end of life and could no longer be supported.

The new control system was based on a Control Techniques Mentor cutter drive with Control Techniques servo motors and amplifiers. A Siemens S7 PLC system with touch screen provided operator control and menu selection.

Cable Armouring Machine Control System

When Prysmian recently merged with the Draka Cables they re-located a number of machines from their Derby plant to Wrexham. The existing Pourtier D.C drive control system was increasingly unreliable and the drives and PLC equipment obsolete so the decision was taken to upgrade the control system at the same time as the relocation.

Drives and Automation were awarded the £100k contract to replace the obsolete Drive and PLC/SCADA system with a new system comprising an Allen Bradley CompactLogix PLC / PanelView HMI/SCADA and Control Techniques D.C and A.C drive controllers.

DC to AC Conversion, Carl Meyer Stone Saw

Drives and Automation were asked to help with completing a DC to AC conversion at a Chesterfield Stone Mill.

The Carl Meyer saw was originally powered with DC Drives and Motors, however aging equipment in an aggressive environment was leading to increased breakdowns and so the decision was made to swap from DC to AC. Mechanically the saw was in good working order.

An AC motor had already been installed on site, however the customer was having difficulties in installing a suitable inverter drive and integrating the new motor into the existing control panel.

AC Drive and I/O upgrade reduces downtime on Wickman / C&M Machine Auto Multi

Drives and Automation were asked to replace the existing control system due to their expertise in process line control and retrofit experience.

The existing obsolete AC drive system was becoming problematic due to documentation, and reliability problems.

These issues were causing significant loss of production due to downtime.

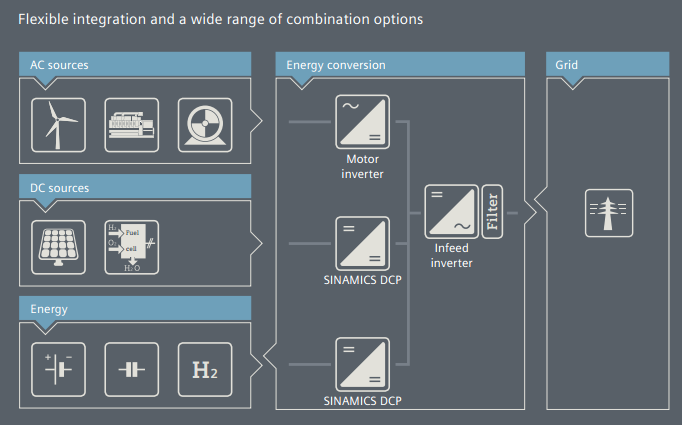

An innovative power take off control system provides bi-directional power flow on a hydrogen fuel cell system.

An innovative power take off control system provides bi-directional power flow on a hydrogen fuel cell system. Our system actively manages power to and from the grid to give local grid support.

Drives and Automation Ltd provided a complete power control system comprising a Siemens Active Line Module (ALM), DC-DC converter; PLC controller and HMI housed within a floor mounted steel enclosure with all necessary control gear and protection.

The power take off system is designed to give bi-directional power flow between the 400VAC mains supply and the 300-480VDC fuel cell. The DC voltage can be set by the user and is actively controlled.

The main control system is based upon a Siemens SINAMICS S120 modular AC Active Line Inverter module.

The system is designed to be controlled by a simply on/off signal; this signal can be derived by manual controls on the HMI or via a remote PLC. Also the voltage setpoint can be adjusted during operation giving a very flexible power supply system.

Youngs Fish Finger Packing Line

Needed: A 12-axis servo controlled packaging machine to pack fish fingers into boxes at a rate of 1200 fingers per minute.

Drives and Automation provided full design, software development, installation and commissioning for electrical equipment for 2 lines in the Grimsby facility. Baldor servo drives and motors are utilised on the line and a 12 Axis TRIO servo motion controller is used for axis synchronisation and cam following.

A CTIU100 HMI was incorporated as an operator interface for the entering of recipes and machine monitoring.

Port of Dublin RORO

Engineering design, software development and commissioning was provided for a ship loading system at the port of Dublin. The bridge structure was raised and lowered utilising 6 variable speed AC driven winches to automatically provide the correct height above sea level. The bridge deck separation was controlled via Hydraulic rams. The top deck also had a telescopic section that traversed out using two motors per side engaged into a rack and pinion. These drives maintain their position to within 1 mm of each other. They also control a locking mechanism using accurate detection of the rack relative to a sprag unit. The drive system is a fully redundant distributed control system utilising Control Techniques Unidrives and CTNet communication.

An Allen Bradley SLC500 PLC with remote I/O provides general operational control with a Panel View 1000 providing a graphical operator interface, all communicating via DeviceNet communications. Communication with the drive system for status and control is via Modbus RTU.

Carter Bros - 900KW 12 pulse Rubber Mixer IRAN

Drives and Automation provided design, manufacture and testing of a reversible mixer for the manufacture of rubber sheet.

The system comprised of two Siemens SIMOREG 6RA70 DC drives configured in 12-pulse mode. The inch reverse function was performed using field polarity reversal.

An overload facility of 220% at start was built into the system design, which included the specification, and procurement or the 12 pulse air cooled phase shift transformer and interbridge reactor.

Variable speed oil supply to the mixing chamber was achieved with a Siemens variable speed 6SE AC drive.

DeviceNet interface via remote I/O to control the system from a remote PLC was also provided.

Scope of supply: -

• Full design and specification

• 12 Pulse transformer and DC Choke

• Manufacture of drive system

• Witness test.

Mechatronic - Laminating Machine Denmark

Drives and Automation provided design, manufacture, software development and commissioning in Denmark for replacement electrical controls of a corrugated card laminating line, manufacturing high quality packaging materials.

Printed laminate card was automatically glued at 120m/min to preformed single face corrugated card stock. The continuous roll of now laminated feed was cut to the final size utilising a rotary shear to an accuracy of better than 2mm in 1000mm. The flying shear was DC driven and the feed of the laminate to the corrugated card was achieved utilising servo control. The laminate sheets were held at rest and accelerated to line speed to ensure correct alignment with the mother sheet was achieved.

A series of individually driven vacuum belts and pinch rolls further treated the material to dry and manipulate the sheets ready for automatically stacking on a choice of 2 stacking machines.

A total of 14 individual drives were locked together via a master line speed reference to achieve the required product specification.

The drives were Eurotherm AC and DC operating in closed loop and flux vector control as appropriate.

Automatic control and line speed referencing was generated within a Siemens Step 7 PLC system. Full backup support was provided in Denmark during the early stages of production, which was achieved on time and to spec.